ACH580 Overview

Catalog: ACH580, 0.75 TO 500 KW, 1 TO 70 HP

The next step in HVAC drives:

The ACH 580 drives come with a range of advanced features that not only provide an excellent user experience, but also make drive integration, commissioning and operation easier than even before.

Scalable performance with full HVAC functionality

ABB HVAC drives come with complete HVAC functionality in a package tailored to your needs and share the same user interface. This makes it easy to choose the optimal product based on installation location and the power output required.

Easy to select and install

Depending on the drive model, all the essentials – chokes, EMC filters, cabling clamps, certified BACnet communication, and enclosures from IP00/UL (NEMA) Type Open to IP55/UL (NEMA) Type 12 – are offered as standard, thus simplifying selection, installation, and commissioning.

Motor control options to meet your application needs

ABB HVAC drives can be integrated with several types of AC motors, including induction, permanent

magnet (PM) and even synchronous reluctance (SynRM) motors. The ability to use these motors can reduce your energy costs even more.

Added flexibility and accessibility

ABB HVAC drives have extensive I/O connections as standard and provide flexibility with additional I/O configurations.

ABB HVAC drives are ideal for all your HVAC applications, such as air-handling units, chillers, and cooling towers. They are suitable for use in a wide range of facilities from residential and commercial buildings to hospitals, data centers, airports and tunnels.

Effortless commissioning and operation: The drive’s HVAC-specific software, intuitive keypad with customizable text and views, and menu-driven programming simplify set-up and operation of even the most complex applications. The optional Bluetooth® capability together with ABB’s Drive tune smartphone app allows you to commission and tune the drive remotely, providing you with access to the same primary settings and other menus available on the drive’s HVAC control panel.

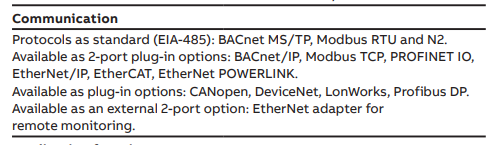

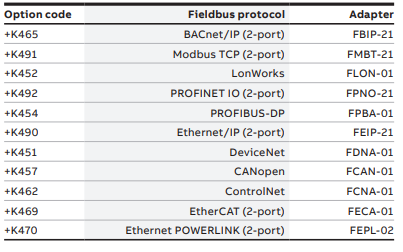

Easy integration into HVAC systems: BTL certified BACnet MS/TP, Modbus RTU, and N2 come as standard in every ACH580 drive. In addition, a wide range of optional fieldbus adapters, including BTL certified BACnet/IP, are available to enable connectivity with all major building automation and control systems.

Clean building power supply: The drive’s active front-end technology secures a unity power factor and the lowest possible level of harmonic distortion in the building. In combination with the ACH580-01 optimized DC choke design, the ACH580 ultra-low harmonic (ULH) drive provides the optimum cost/performance ratio in the industry.

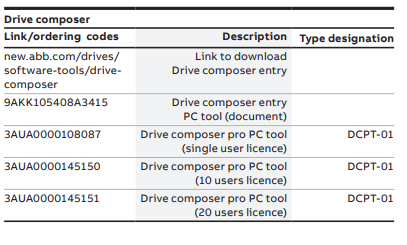

Advanced software tools for easy configuration, startup and maintenance: Drive composer is a state-of-the-art PC tool, which can be simply connected to the drive’s control panel via a USB interface. It supports

startup, configuration, monitoring and process tuning. Cold configuration for unpowered drives saves time as parameters can already be set in the warehouse, thanks to the CCA-01 cold configuration adapter.

Premier HVAC control:

We understand the complexity of air handling systems and the need to produce high levels of comfort, control, and safety. Be assured that, regardless of the season or external conditions, we help make your system efficient, safe, and informative.

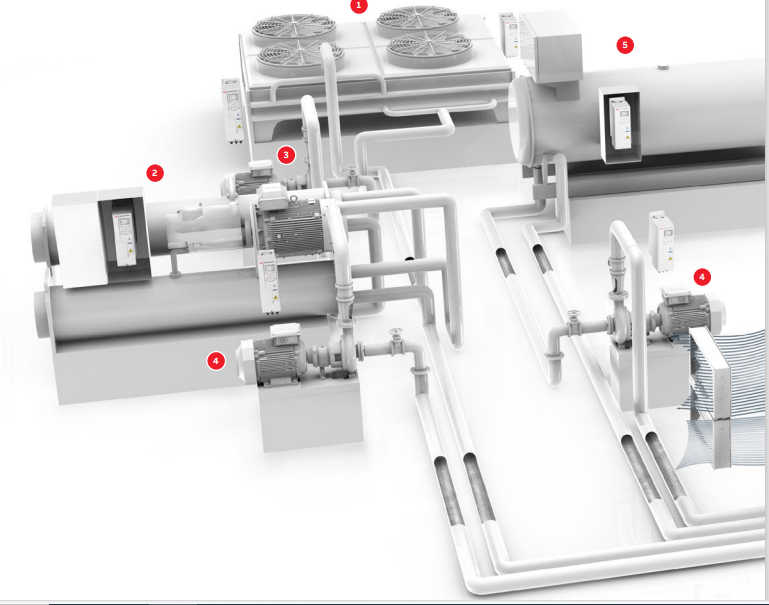

1 Cooling tower

Cools down the condenser water.

- The drive controls the speed of multiple fans simultaneously to achieve high energy savings, while optimizing the installation cost.

2 Chiller

Chills water or other liquid to cool down and dehumidify the indoor air.

- The drive controls the speed of the compressor for better energy efficiency

- By-pass valves can be avoided

- Less mechanical stress as there are less starts and stops

- Mechanical resonance speeds can be avoided

- Maximum speed is not limited by nominal supply frequency

- Less stress to supply network as high inrush currents can be avoided with VFD controlled start.

3 Condenser water pump

Circulates water between the cooling tower and the chiller.

- Energy savings can be achieved with variable frequency drives that adjust pump speed to the cooling load.

4 Chilled and hot water circulator pumps

Circulate water (or other liquid) between heating coil and boiler or cooling coil and chiller.

- The cooling and heating loads vary a lot over time. Speed controlled circulator pumps make

sure, that an adequate amount of water or other liquid is distributed in the building. - Soft start and stop of the pump reduce hydraulic stress on pipelines and valves.

5 Boiler

Heats up the water for building heating.

- The drive controls the burner fan to adjust the amount of combustion air to the heating load.

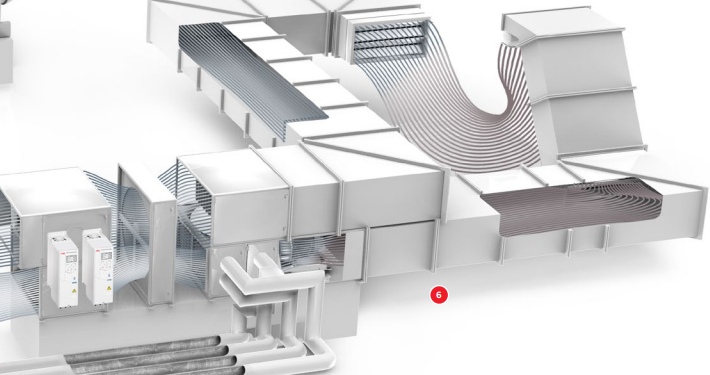

6 Air handling unit

Circulates, mixes, cleans, humidifies/ dehumidifies, heats/cools air.

- Drives can be used to

- control the speed of supply and return fans

- eliminate mechanical stress of air duct system

- avoid fan resonance speeds

- control the speed and efficiency of the rotary heat exchangers

- control the dampers

- monitor AHU condition including filter clogging, fan belts and heating coil freeze

- ABB HVAC drives also have an override mode, which secures drive operation in emergency situations

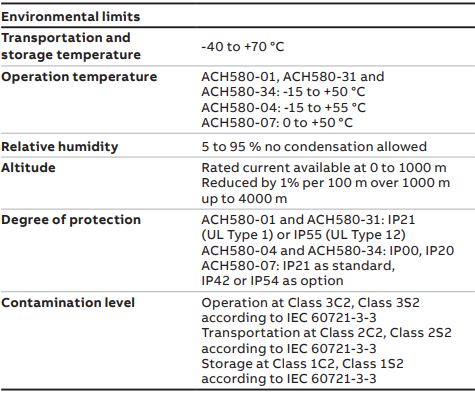

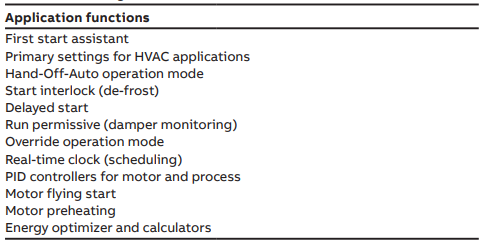

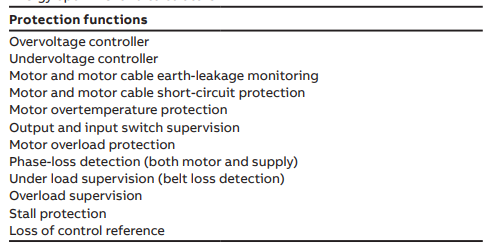

Common characteristics for the ACH580 HVAC drives family:

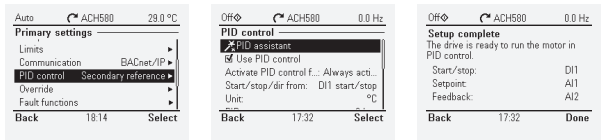

HVAC control panel with primary settings

- Primary settings make commissioning of the drive easier than ever before

- An optional Bluetooth® enabled control panel allows easy smartphone connection and remote support possibilities

- Easily available USB interface for PC and tool connection

- Help button for problem-solving.

HVAC communication protocols

- BTL certified BACnet MS/TP and other common HVAC communication protocols such as N2 and Modbus RTU as standard

- BACnet/IP with an internal fieldbus option.

Suitable for various HVAC applications

ABB HVAC drives are suitable not only for variable torque applications like fans and pumps, but also for basic constant torque applications like compressors.

Robust and reliable design

- All units are tested under full load in maximum allowed ambient temperature to verify the quality

- Printed circuit boards are protected with extra coating to be able to operate in humid and harsh environments

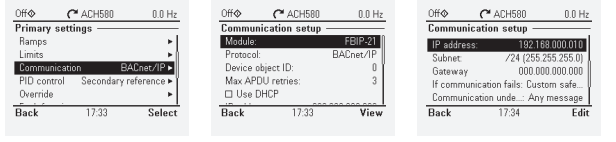

Energy efficiency calculators Optimize energy efficiency with features that help you to save and manage energy. You can monitor the hourly, daily cumulative, last hour, last day and last month energy consumption via kWh counters.

Diagnostic menu Analyze and resolve issues with the control panel’s diagnostics menu. You can quickly analyze why the drive is performing as it is; running, stopped or running at the present speed.

Shared features of the ABB all-compatible drives portfolio:

Drivetune smartphone app

The Drivetune smartphone app together with the Bluetooth® enabled control panel allows you to set up and commission the drive remotely from a safe and comfortable location, using the same primary settings menu that is available on the control panel on the drive.

Integrated and certified Safe torque off (STO)

- TÜV-certified Safe Torque Off helps to build functionally safe HVAC machines and you can

document the safety functions in the equipment - Embedded STO is certified to SIL 3/PL e.

Embedded load analyzers

Analyze and optimize the application with the load profile log, which shows how the drive has

operated.

EMC/RFI category C2

- EMC category C2 level design allows installation in commercial and residential buildings so called first environment

- Option to increase EMC compliance to C1 level

Integrated process control Reduce costs with the built-in HVAC controllers. They allow the HVAC drives not only to control themselves using an external feedback signal, but also, to control other processes, such as your rotary heat exchanger or you’re heating and cooling coils.

Flexibility in programming

Scale up and customize the drive to your application’s requirements with flexible parameter pointers or visual adaptive programming.

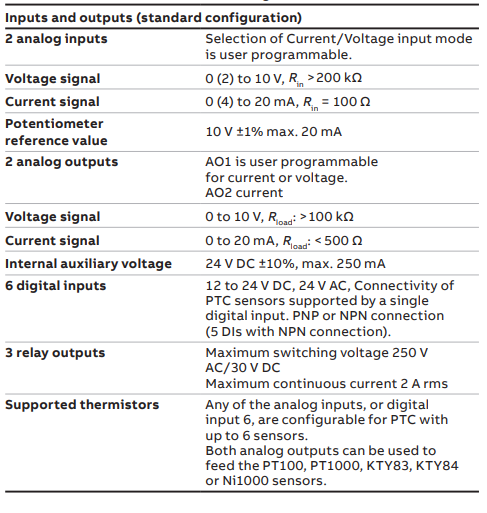

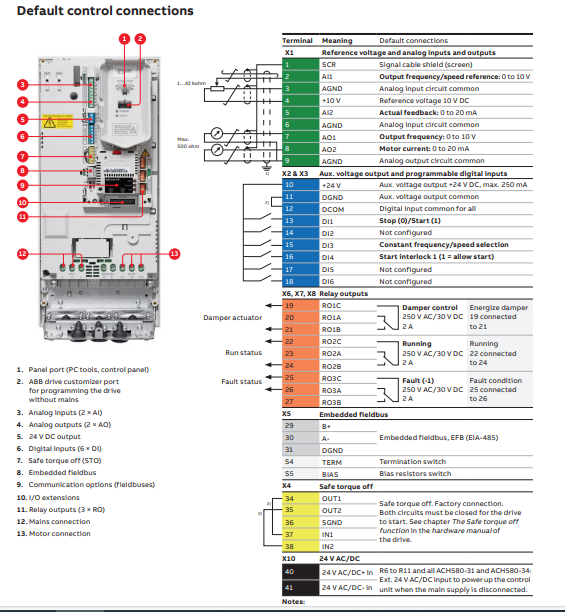

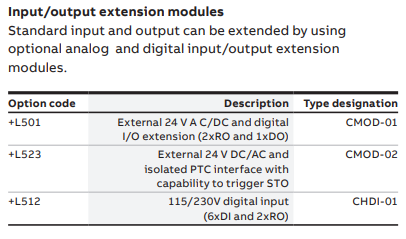

Extensive I/O capabilities

- ABB HVAC drives have an extensive number of I/O terminals in standard configuration

- Colored terminals and clear terminals marking significantly ease drive wiring process

- I/O status can be monitored via I/O menu

- I/O can be forced on or off to verify drive’s either from the display or via your fieldbus connected controls.

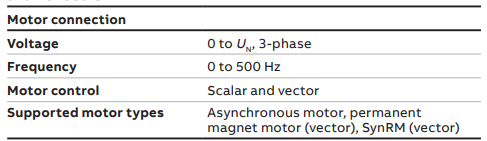

- Advanced motor control

- Support for induction (IM), permanent magnet (PM) and synchronous reluctance (SynRM) motors

- Reduce audible motor noise by spreading the switching frequencies over user-specified range

Same PC tools for ABB all-compatible drives The Drive composer PC tool can be downloaded for free from new.abb.com.

Connectivity

- ABB’s F-series fieldbus adapters can be used throughout the all-compatible platform

- Mobile phone connectivity via the optional Bluetooth® assistant control panel

- Fieldbus settings are made easy with the Primary settings menu.

ACH580 ultra-low harmonic (ULH) drive:

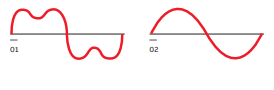

What are harmonics?

In an ideal case the current in an AC grid is a pure sine wave and does not contain harmonics. In reality the current deviates from this pure sine wave and contains harmonics. Harmonic current is typically measured as a percentage value, called total harmonic distortion (THDi).

Harmonics can cause damage to sensitive electronic equipment, interference to communication

equipment, tripping of circuit breakers, blowing of fuses and capacitor failures. The effects

can also include overheating of cables and motors, overloading of transformers, generator failure and

power factor capacitor damage.

Complete HVAC functionality

The ACH580 ULH comes standard with an intuitive control panel used to configure, control, and monitor the drive. An optional Bluetooth control panel allows the drive to be configured via the control panel or the DriveTune app. A robust HVAC firmware package provides drive, motor, and application protection features. Application specific features, such as accepting four separate start interlocks (safeties), along

with broken belt detection, are also included. The drive includes BACnet MS/TP, Modbus RTU, and Johnson Controls N2 as standard.

Savings in total cost of ownership

Installation costs are reduce with the simple three wires in and three wires out design. Maintenance costs are lowered as compared to other harmonic mitigation solutions like passive filters, multi-pulse and active filters there are less components to maintain and stock as spares.

Using the ACH580 ULH allows your engineer to design your electrical system and backup generators to the right size and not oversizing for the harmonics in the network.

Reliability for your building

Harmonics in the network could cause problems with other electrical equipment in the same electrical network. In the worst case it might cause your sensitive electrical equipment to fail. Harmonics can cause problems also in retrofit projects. In such projects, a transformer might not be able to meet the harmonic levels caused by nonlinear loads such as standard 6-pulse drives, so there is a risk of overloading the transformer. In addition to problems caused by harmonics, also weak network can cause troubles to your

systems. Weak electrical networks that have sags in line voltage may cause motors to overheat,

trip or fail. The ACH580 ULH drive offers a reliable solution to overcome these challenges as it is able to lower the harmonic content so that sensitive equipment stays running and transformers or generators

don’t fail. Also, the ACH580 ULH can boost output voltage so that motor always runs with nominal voltage despite the fluctuations in line voltage.

Optimized size and performance

ACH580 ULH has all the harmonic mitigation technology in the drive. With a THDi of 3% or less, there is no need to install external components for reducing harmonics, this drive doesn’t create the harmonics to fix.

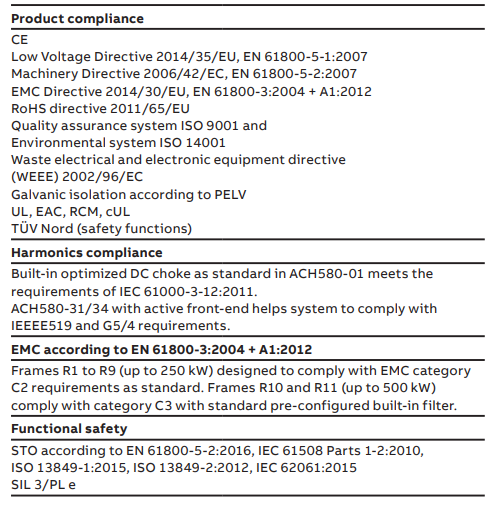

Complete HVAC drive offering

No matter the frame size or power, all ABB HVAC drives offer ease of use, scalability, and quality.

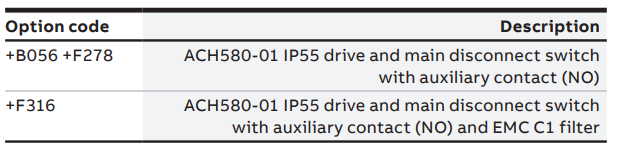

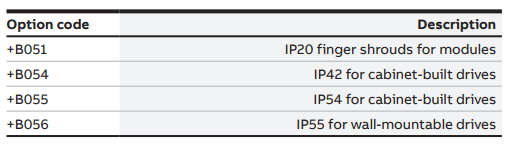

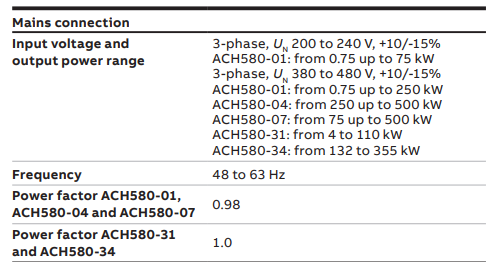

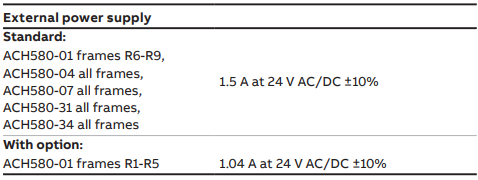

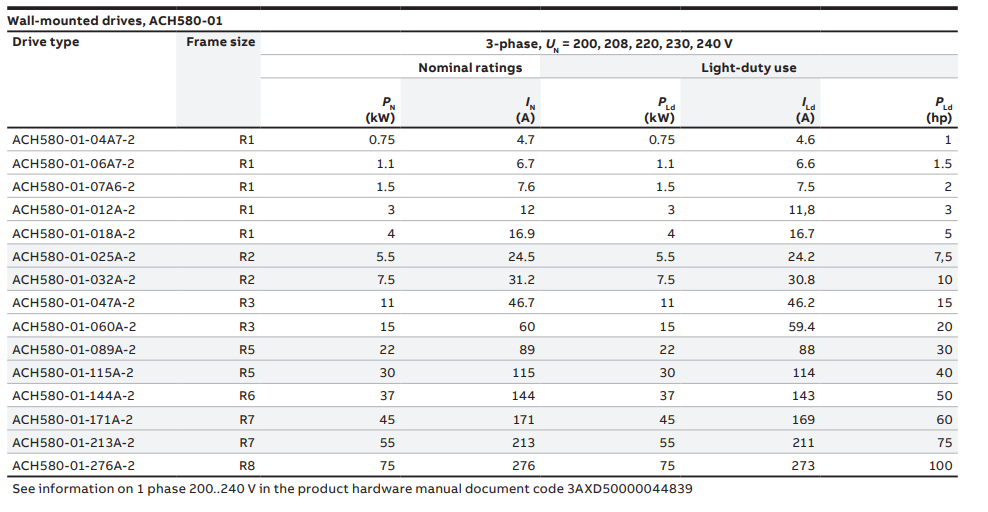

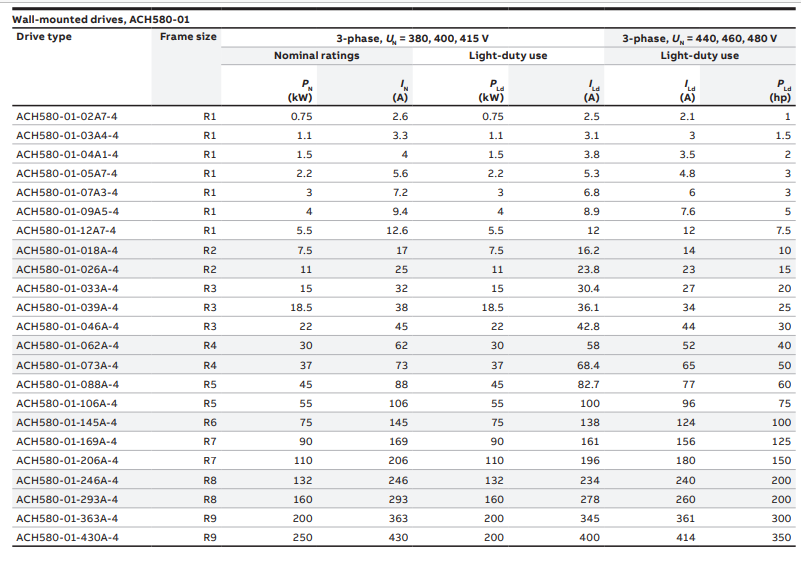

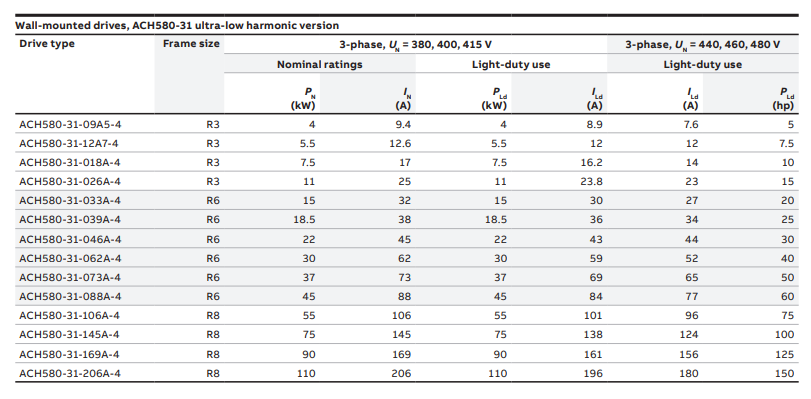

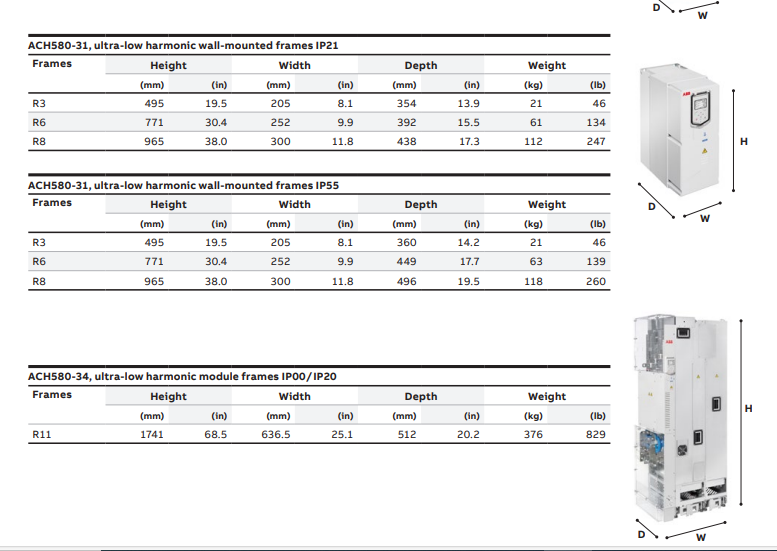

Wall-mounted drives, ACH580-01 and ACH580-31 ultra-low harmonic version

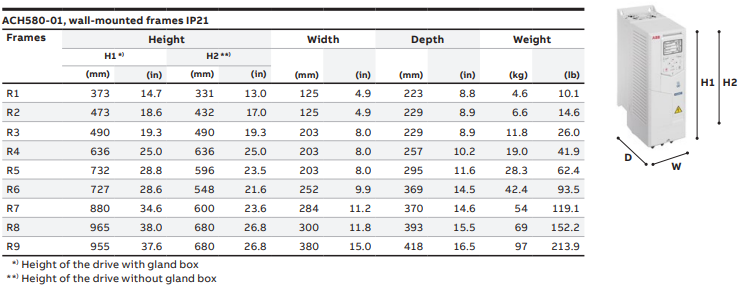

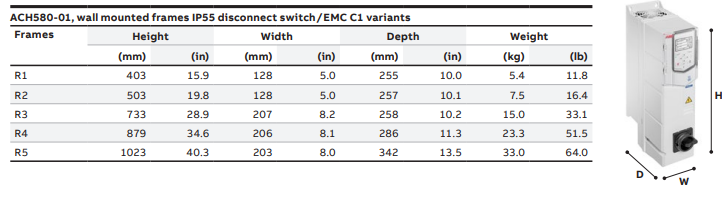

ACH580 wall-mounted drives are available in IP21/UL (NEMA) Type 1 to IP55/UL (NEMA) Type 12 protection class with a power range up to 250 kW/350 hp for ACH580-01 and up to 110 kW/150 hp for ACH580-31 ultra low harmonic variant. Drives offer side-by-side, flange, and horizontal mounting options.

The IP55/UL (NEMA) Type 12 variants are designed for applications exposed to dust, moisture, vibration, and other harsh conditions.

The ACH580-01 is a six-pulse drive that includes an optimized DC choke for harmonic mitigation.

ACH580-31 ultra-low harmonic drives with built-in harmonics mitigation solution help to keep the power network clean providing exceptionally low harmonic content. This brings significant benefits, including improved reliability and increased energy savings, as well as extended equipment lifetime.

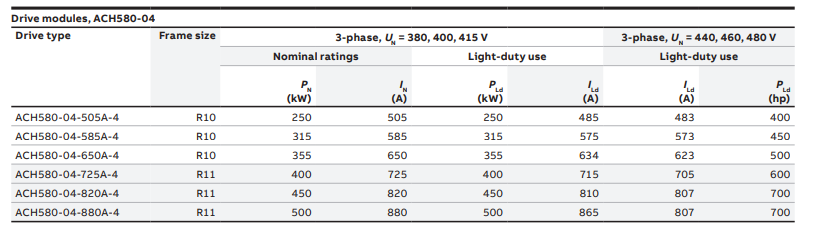

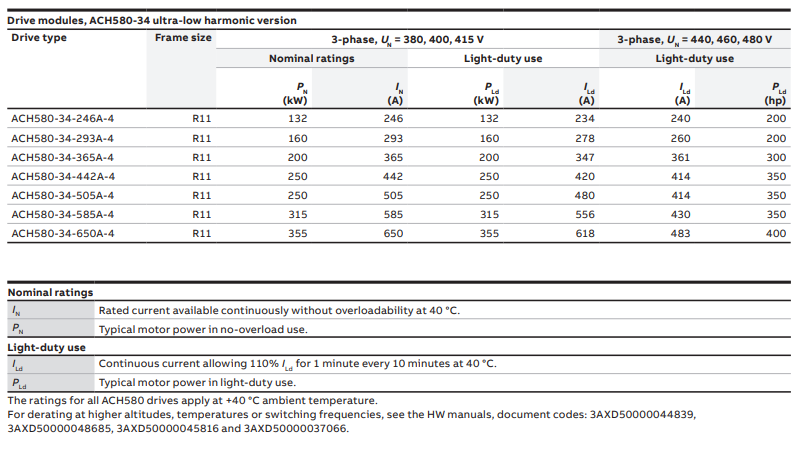

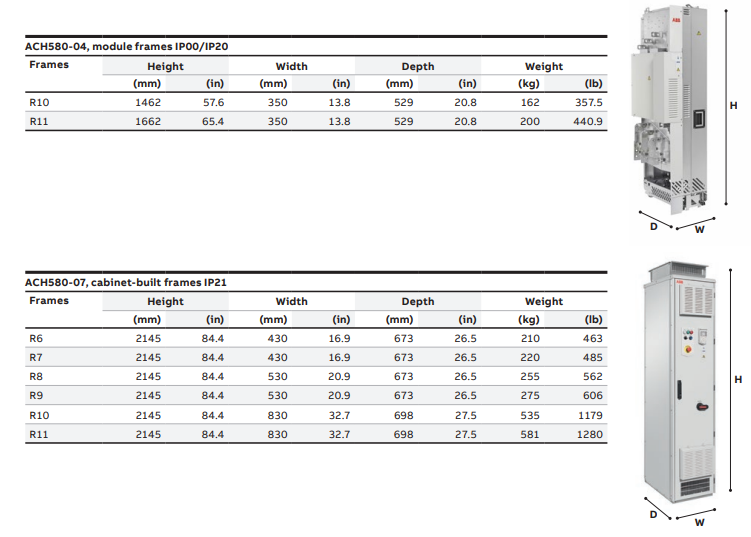

Drive modules for cabinet installation, ACH580-04 and

ACH580-34 ultra-low harmonic version

ACH580 drive modules are perfect for system integrators, cabinet builders, and OEMs who want to optimize cabinet design using ACH580-04 in power range 250–500 kW or ACH580-34 ultra low harmonic version in power range 132–355 kW without compromising on easy installation, commissioning and maintenance.

The ACH580-04 comes with a choke for harmonic mitigation and ACH580-34 has embedded active front-end solution keeping harmonics content in the network to a minimum.

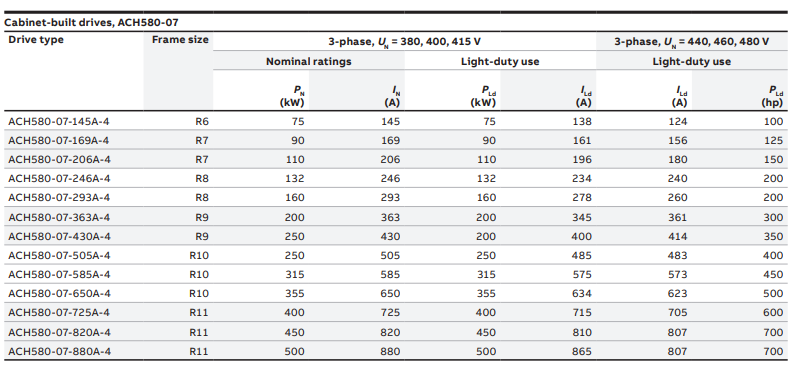

Cabinet-built drives, ACH580-07

Cabinet-built ACH580-07 drives are available with IP21 protection class as standard (with optional IP42 and IP54 enclosures) in frame sizes R6 to R11. The drives feature a new cooling arrangement and a high-quality, global cabinet design. Available in a power and voltage range of 75–500 kW and 3-phase, 380–480 V. ACH580-07 drives always have chokes for harmonic mitigation built-in.

Main disconnect switch for increased safety

Main disconnect switch

The main disconnect switch option provides a possibility to disconnect the drive from the main supply when needed. This prewired main disconnect switch option saves time, money and space as it is integrated in the drive. There is no need to install additional, external isolation devices to the supply side of the drive. The option improves safety as it is always visible, when operating on the drive. Auxiliary contact allows signaling the switch position to BMS to avoid unnecessary controller alarms. The switch can be padlocked to open position to disable drive operation during e.g. maintenance.

High protection for operation in harsh environments:

Thanks to the drive’s wall-mountable construction in both IP21 and IP55 configurations the ACH580-01 can be installed in clean rooms, and even dusty and wet environments. The cabinet-built variant comes with IP21 as standard and is also available with IP42 and IP54 protection classes for use in harsh environments. The robust, protective design ensures that no additional enclosures or components, such as dust filters and fans, are needed. Overall, drives for harsh environments require smaller capital expenses by avoiding or advancing maintenance of external components, which in turn improves the reliability of the drive and the process.

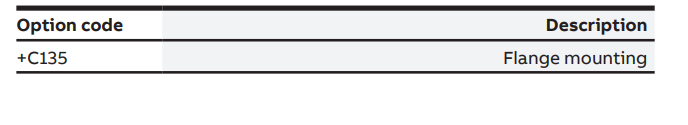

Reduced Panel Cooling Need:

The ACH580-01 wall-mounted drive offers flange mounting as an option, separating the control electronics from the main circuit cooling airflow, saving space and ensuring optimal cooling. This results in better thermal management during panel installation and reduces the overall enclosure size. Furthermore, the need for air-conditioning can often be eliminated, as up to 80 percent of the heat load is removed through the back of the panel.

Advanced Cooling:

The simple and robust design of the ACH580-07 cabinet-built drive ensures reliable operation, even in

harsh environments. The flange-mounting feature is standard for the cabinet-built ACH580 drive, which

separates the heat-generating power electronics from the more sensitive control electronics and extends the product’s lifetime. The hot air can be ducted away from the motor control center, reducing the need for air-conditioning significantly.

Ultimate efficiency and reliability to optimize your system’s total cost of ownership:

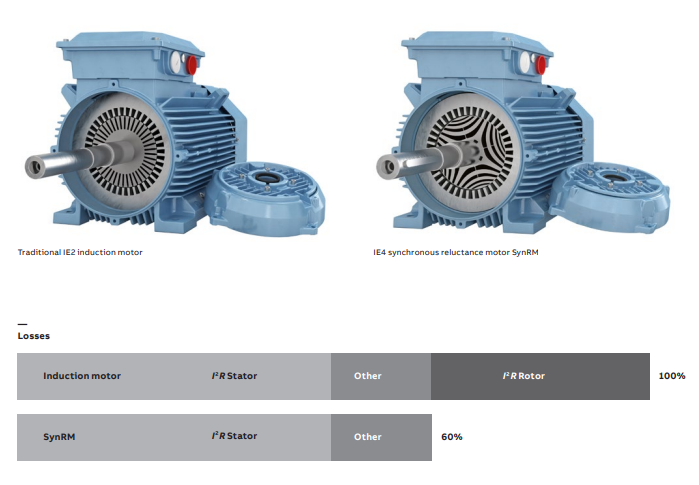

Innovation inside

The idea is simple: Take a conventional, proven stator technology and a totally new rotor design. Then combine them with a dedicated HVAC industry drive loaded with new, application-specific software. Finally, optimize the whole package for applications such as fans, pumps, compressors, air-handling units and chillers.

Magnet-free design

Synchronous reluctance technology combines the performance of a permanent magnet motor with the

simplicity and service-friendliness of an induction motor. The new rotor has neither magnets nor windings and suffers virtually no power losses. And as it has an identical footprint, it is easy to replace an induction motor with a SynRM.

Superior reliability to minimize the cost of not running

IE4 synchronous reluctance motors have very low winding temperatures, which increases the reliability and life of the winding. More importantly, a cool synchronous reluctance rotor means significantly lower bearing temperatures – an important factor because bearing failures cause about 70 percent of unplanned motor outages.

Choose the motor for your HVAC application:

Choose the best motor for your application. A natural match for induction motors, ABB HVAC drives can also control high-efficiency motors such as permanent magnet or synchronous reluctance motors for greater efficiency.

Induction motors, the industry workhorse

Pair the ACH580 with an induction motor (IM) for simple and reliable operation in many HVAC applications and in a wide range of environments. Further simplifying setup, the HVAC drives can be integrated with virtually any type of IM by entering the nameplate motor data only.

Permanent magnet motors for smooth operation

ABB has the software, hardware and application knowledge to support PM motor technology. PM technology offers users high efficiency across the speed range and customized housing for applications such as fan walls and cooling towers, as well as eliminating the need for mechanical speed reduction equipment.

IE4 SynRM for optimized energy efficiency

Combining ABB’s HVAC drive control technology with our synchronous reluctance motors will give you a motor and a drive package that ensures high energy efficiency, reduces motor temperatures, and provides a significant reduction in motor noise. The key is in the efficiency-optimized rotor design of our SynRM motors.

All-compatible drives portfolio

The all-compatible drives share the same architecture, software platform, tools, user interfaces and options. Yet, there is an optimal drive from the smallest water pump to the biggest cement kiln, and everything in the between. When you have learned to use one drive it, is easy use the other drives in the portfolio.

Automation Builder Engineering Suite

Automation Builder integrates then engineering and maintenance for PLC, drives, motion. HMI and robotics. It complies with the IEC 61131-3 standard offering all five IEC programming languages for PLC and drive configuration. Automation Builder supports a number of languages and comes with new libraries. FTP functions, SMTP, SNTP, smart diagnostics and debugging capabilities.

AC motors

ABB’s low voltage AC motors are designed to save energy, reduce operating costs and enable demanding motor applications to perform reliably and without unscheduled downtime. General performance motors combine convenience and easy handling seamlessly with ABB’s engineering expertise. Process performance motors provide the most comprehensive.

Control panels

Our control panels offer a wide range of touchscreen graphical displays from 3.5” up to 15”. They are provided with user-friendly configuration software that enables tailor made customized HMI solutions. Rich sets of graphical symbols and the relevant drivers for ABB automation products are provided. Control panels for visualization of AC500 web server applications are available.

Soft starters

ABBʼs softstarters increase a motorʼs lifetime by protecting it from electrical stresses. With everything that you need in one unit, from bypass contactor to overload protection, a single Soft starter makes for a compact and complete starting solution.

AC500-eCo

Meets the cost-effective demands of the small PLC market while offering total inter-operability with the core AC500 range. Web server, FTP server and Modbus-TCP for all Ethernet versions. A Pulse Train Out-put module is available for multi-axis positioning.

Technical Data

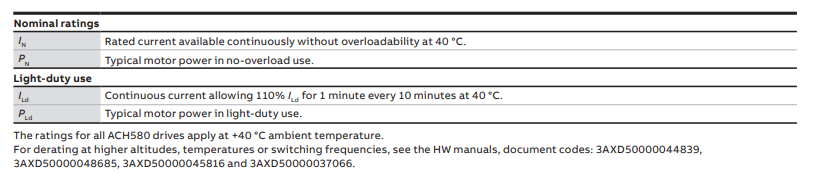

Ratings types and voltages:

Dimension:

ACH580 Standard I/O diagram:

Control Panel Options and Mounting Kit:

The standard delivery of the ABB HVAC drives include the HVAC control panel, which has the Hand-Off Auto operation logic and multiple other HVAC features. A variety of different control panel accessories are available for ACH580 drives.

Bluetooth control panel ACH-AP-W

The optional Bluetooth panel enables connection with the Drivetune mobile app. The app is available for free from Google Play and the Apple App store. With the Drivetune app HVAC users have all the similar functions as there is on the standard ACH-AP-H or ACH-AP-W ncontrol panels: Primary settings, I/O menu, diagnostics and full parameter list among other functions.

Control panel bus adapters CDPI-01

Control panel bus adapters are used to connect HVAC control panels with a RJ-45 cable to the drive from a distance, e.g. when mounting the control panel on a cabinet door. In addition, CDPI adapters can be used to daisy chain several ACH drives together to be controlled with a single control panel or PC tool.

Control panel mounting kit for outdoor installation DPMP-04/05

Enables control panel outdoor mounting thanks to IP66 protection class, UV resistance and IK07 impact protection rating.

Control panel mounting platform DPMP-01

This mounting platform is for flush mountings. This requires also CDPI-01 for ACH580 (blank control panel with the RJ-45 connector) and a control panel.

Control panel mounting platform DPMP-02 for ACH580-01 and ACH580-31, DPMP-03 for ACH580-04 and ACH580-34

This mounting platform is for surface mountings. This requires also CDPI-01 for ACH580 (blank control panel with the RJ-45 connector) and a control panel (HVAC, Bluetooth® or industrial).

Door mounting kits DPMP-EXT for ACH580-01 and ACH580-31

The door mounting kit is ideal for cabinet installations. Should you want to use a different control panel than the one delivered with the drive, it needs to be ordered separately.

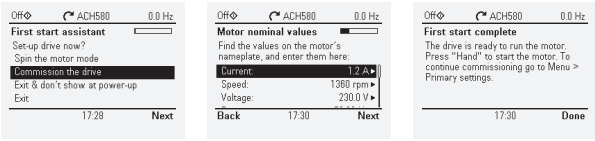

Easiness on a whole new level:

Enjoy the simplicity with the assistant control panel’s intuitive user interface, assistants and ready-made macros. The panel guides you through commissioning without a need to know any drive parameters and helps in unclear situations.

Assistant control panel, ACH-AP-H

Set up the drive, fine-tune motor control and monitor values that matter using the assistant control panel,

delivered as standard with all HVAC drives.

Commission without a hassle Select language, set time and date, name the drive, enter motor values, test rotating the motor.

Primary settings Commission HVAC controllers with the intuitive PID assistant. Set the communication up. Tune the limits, commission override function, set the ramps, everything can be done with primary settings.

Home view displays Effortlessly monitor the values that are the most important to you. You can select values for monitoring from a ready-made list or choose user-defined parameters.

Help button: The help button provides more information about your selection, and it can be pressed in any view.

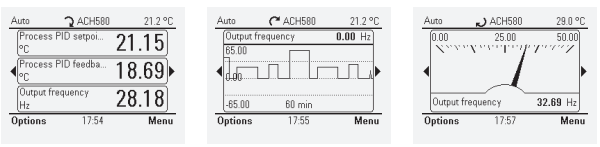

Tools:

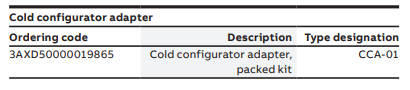

Enjoy the easiness offered by the cold configuration tool and Drive composer PC tool. These tools lighten your workload, especially if there are many drives. The cold configurator tool provides a quick way to parametrize unpowered drives even in their boxes, and the Drive composer PC tool offers advanced means, for example, for commissioning and monitoring.

Safe configuration for unpowered drives The CCA-01 cold configuration adapter provides a serial

communication interface for unpowered drives. With the adapter, safe isolation of both serial communication and control board power supply is possible. The power supply is taken from a PC USB port.

PC tools

The Drive composer PC tool offers fast and harmonized setup, commissioning, monitoring and the capability to create adaptive block programs. The free version of the tool provides startup and maintenance capabilities and gathers all drive information, such as parameter loggers, faults, and backups into a support diagnostics file. Drive composer pro provides additional features such as custom parameter windows, graphical control diagrams of the drive’s configuration, and improved monitoring and diagnostics.

I/O Options:

ABB HVAC drives are very flexible in terms of I/O configuration. The standard I/O is suitable for most HVAC applications. On top of that, ACH580 provides great flexibility with different I/O options.

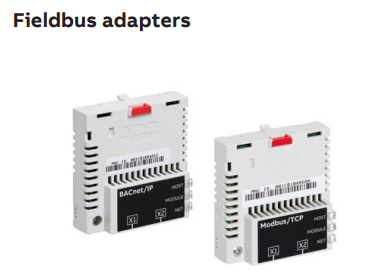

Fieldbus Option:

The HVAC communication protocols BACnet MS/TP, Modbus RTU and N2 are there as standard. Should that not be enough, the other protocols are supported with optional adapters.

BACnet/IP option

Native BACnet/IP allows for greater bandwidth for more frequent polling/ monitoring and more devices on the same sub-network. Thanks to the two-port design of this adapter, the need for external switches and installation time are reduced. Different buildings may have different fieldbuses, and we have multiple option modules to satisfy your needs.

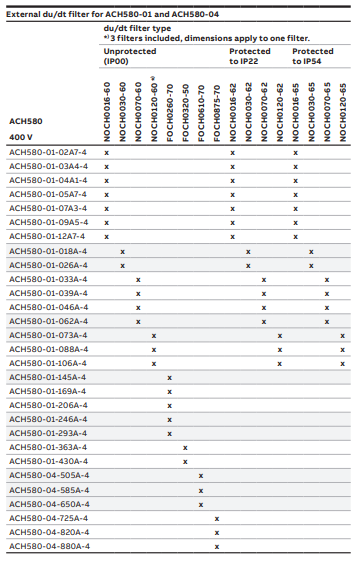

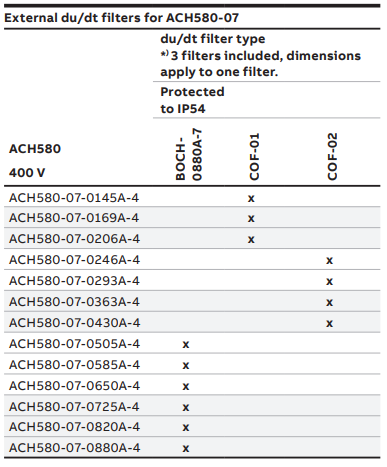

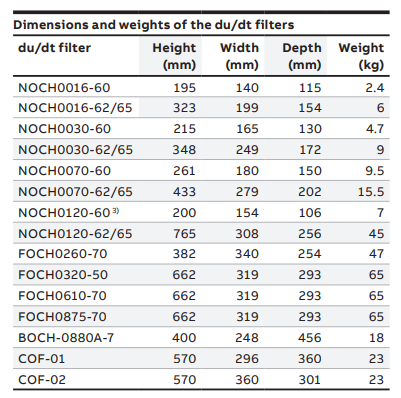

du/dt filters:

du/dt filtering suppresses inverter output voltage spikes and rapid voltage changes that stress motor insulation. Additionally, du/dt filtering reduces capacitive leakage currents and high- frequency emissions from the motor cable as well as high-frequency losses and bearing currents in the motor. The need for du/dt filtering depends on the motor insulation. For information on the construction of the motor insulation, consult the manufacturer. More information on the du/dt filters can be found in the ACH580 hardware manual.

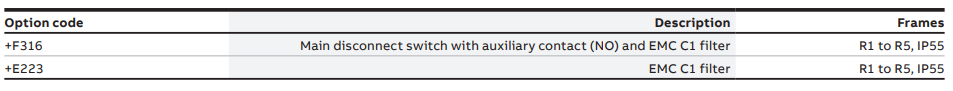

C1 filters for ACH580-01

Selection Guide:

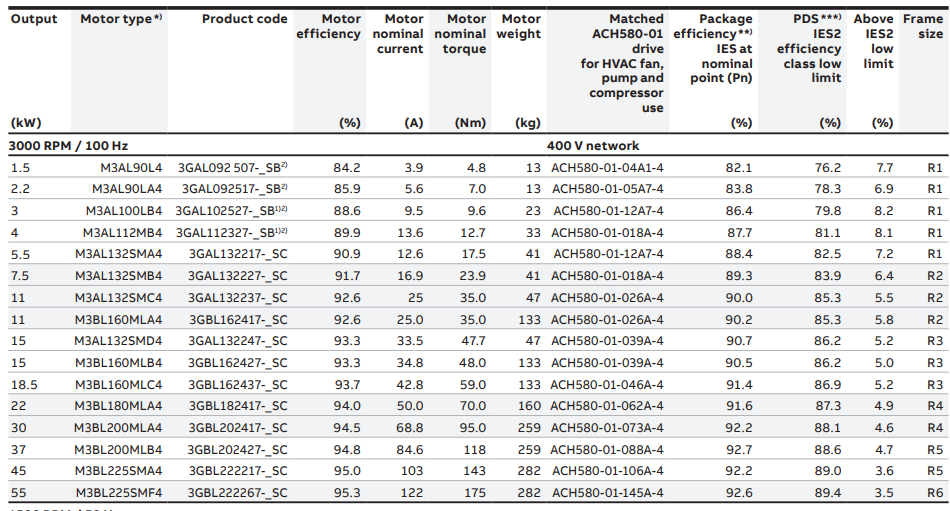

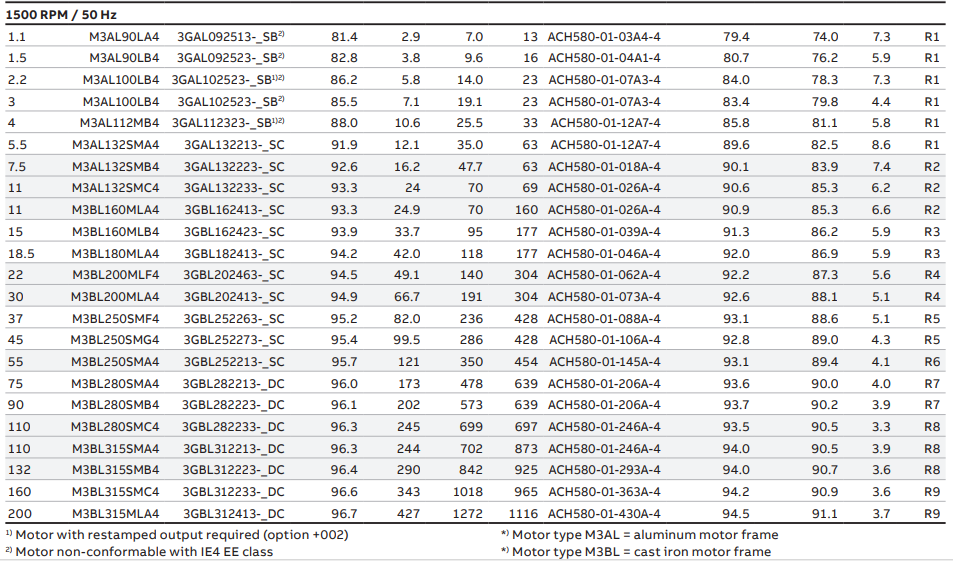

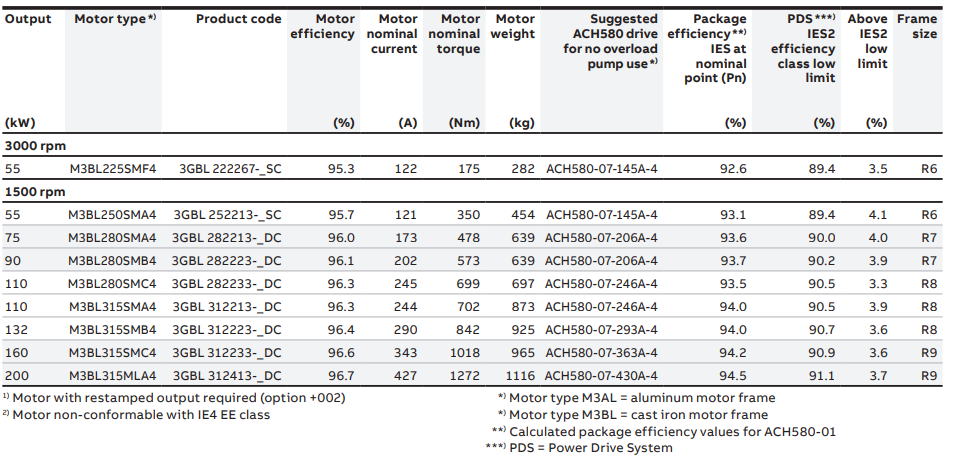

IE4 synchronous reluctance motors:

This table presents technical performance data for IE4 SynRM motors. Variant codes and construction details are based on the M3BP motor. Protection IP55, cooling IC 411, insulation class F, temperature rise class B. Motor values are given with an ACH580 drive supply.