CH-05 ACS 5000W Excitation Unit

Objective:

After completing this module, you will be able to understand and explain to others: Basic operation and principles of field exciters for synchronous motors, excitation systems used with ACS 5000. Main power diagram of ACS 5000 water cooled Excitation Units, both direct and brushless. Control equipment of the ACS 5000 water cooled Excitation Units, function and settings of the control boards.

ACS 5000 Excitation System:

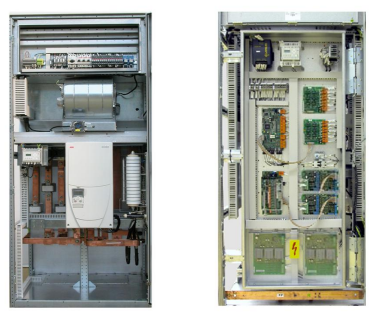

The Excitation Unit of ACS 5000 is a current controller based on the thyristor technology. The ACS 5000 converter for synchronous motors can be equipped with one of these two types of Excitation Unit: Air cooled excitation, based on a standard ABB DC drive, DCS 800, and Water-cooled excitation, based on ABB Cycloconverter drive technology. In both versions, air or water cooled, the Excitation Unit is delivered in a separate cabinet, as part of ACS 5000 drive for a synchronous motor. Depending on the drive size, the Excitation Unit can be delivered in the same transportation unit, or separate, and usually it is the rightmost unit in the ACS 5000 converter line-up. In this module we will discuss about the water-cooled excitation system. We can call it “CCB system”, after the name of the main control board of the thyristors bridge: Converter Control Board, CCB.

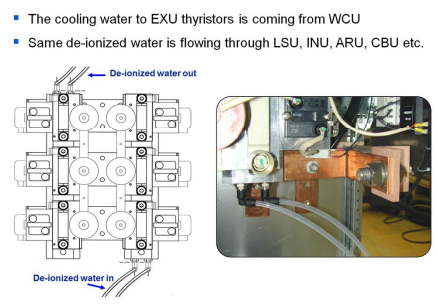

CCB- Excitation System Water Cooling:

The power stage in the water cooled EXU is cooled down by the same de-ionized water flowing through the water cooled ACS5000. Two valves, V30 and V31, are installed in the Water-Cooling Unit in order to supply the CCB Excitation Unit with the de-ionized water.

Direct Excitation:

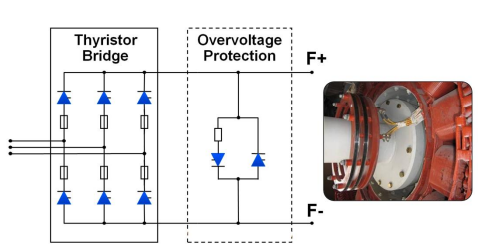

The CCB Excitation Units are available for two excitation methods of the synchronous motor: Direct or AC brushless. The direct excitation system consists of six pulses thyristor-controlled rectifier and an overvoltage protection circuit. The overvoltage protection circuit is present only in the direct excitation EXU.

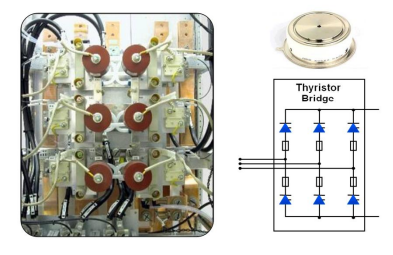

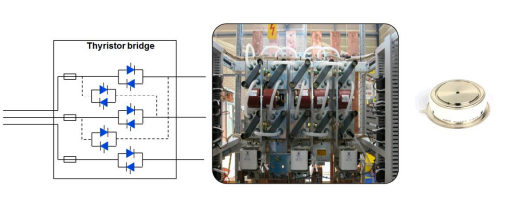

Direct Excitation-Thyristor Bridge

The thyristor bridge consists of six thyristors cooled by the same de-ionized water as the rest of the drive. Each thyristor has its own fuse. They are fired by a Gate Driver Board through six pulse transformers. Valves V30 and V31 in the Water-Cooling Unit supply the cooling water for the Excitation Unit.

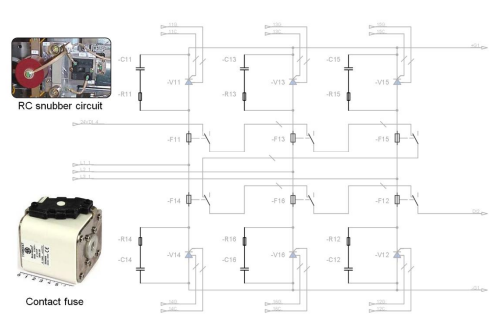

Each thyristor branch is protected against short circuit by a contact fuse. The contacts of all the fuses are connected in series and directed to a Digital Input, DI2, of the Pulse Amplifier Interface PAI. In parallel with each thyristor there is a RC snubber circuit, to protect the thyristors against excessive voltage transients during the commutation.

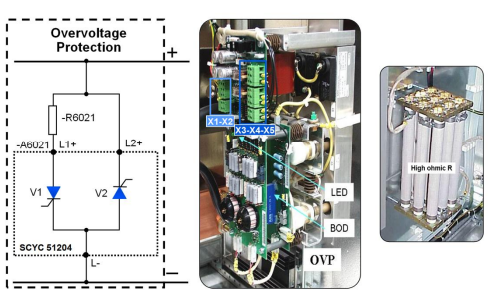

Direct Excitation- Overvolt Protection:

The overvoltage protection circuit protects the EXU against accidental overvoltage from both supply line side and motor excitation side. An overvoltage protection device will suppress the overvoltage by turning ON one of the thyristors V1 or V2. V1 suppresses positive overvoltage, across a group of resistors R6021, and V2 suppresses negative overvoltage. A control board OVP supervises the operation of the overvoltage circuit. OVP detects an overvoltage by the mean of a Break Over Diode, BOD. A green LED indicates “power supply OK”. Two red LED’s indicate that an overvoltage was detected: LED V32 for the thyristor V1, and LED V33 for the thyristor V2. The OVP board has five connectors: X1: 24 VDC power supply X2: Digital Input, EXTERNAL RESET from PAI board, Digital Output DO1 X3: Digital Input, FIRING PROTECTION signal from the same PAI board, DO2 X4: Digital Output, thyristor V1detected overvoltage X5: Digital Output, thyristor V2 detected overvoltage X4 and X5 are connected in series and sent to PAI

board, Digital Input DI4.

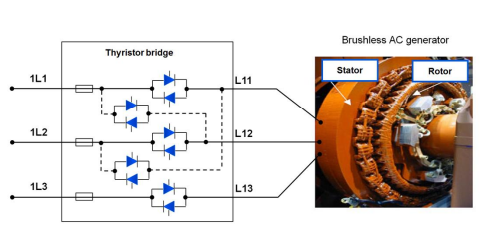

Brushless Excitation:

In the brushless excitation EXU, the stator of the exciter machine is fed with controlled AC by way of three groups of two thyristors in anti-parallel. Two other groups are installed in a cross connection between 1L1 – L12 and 1L2 – L11 in order to change the phase rotation when the synchronous motor changes the direction.

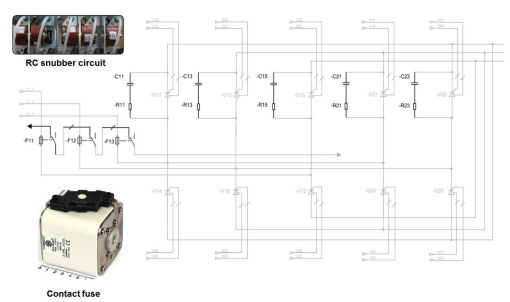

Brushless Excitation-Thyristor Bridge:

The power stage of the brushless excitation consists of five groups of two thyristors in anti-parallel. The heat sinks are integrated in the drive water cooling circuit. The ten thyristors are fired by two Gate Driver boards, by the mean of ten pulse transformers.

The Excitation Unit is protected against short circuit by three contact fuses F11, F12, F13 installed on the input line. The contacts of the fuses are connected in series and directed to a Digital Input, DI2, of the Pulse Amplifier Interface PAI. In parallel with each thyristor group there is a RC snubber circuit, to protect the thyristors against excessive voltage transients during the commutation.

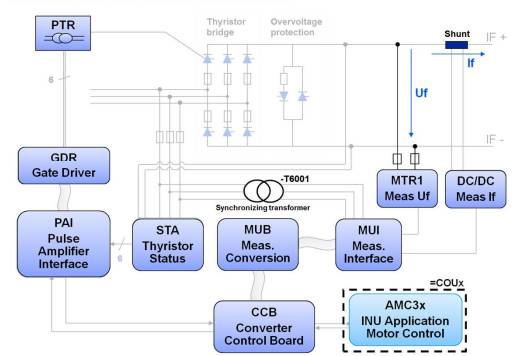

Control Hardware In Direct Excitation:

The excitation control software is implemented in the AMC and CCB boards. The AMC board, Application and Motor Controller, is located in the control cabinet of the synchronous inverter and connected via fiber optic cables to CCB, Converter Control Board, in the excitation cabinet. AMC board is responsible for the calculation of the required excitation current, which is sent to CCB as a set point. All the other excitation control boards are located in the Excitation Unit. PAI, Pulse Amplifier Interface, is a logical amplifier: it receives the firing pulses from CCB in a serial form and converts them in parallel signals. It sends back to CCB information about the excitation converter status. The communication CCB – PAI is also fiber optic. A Thyristor Status Board, STA, delivers to PAI, via six fiber optic cables, the actual status of each thyristor by measuring the input AC voltages and the output DC voltage. PAI board sends further the firing signals to the Gate Driver board GDR, via a 20-pins ribbon cable. A GDR board can control 6 Pulse Transformers, PTR, Pulse Transformers apply the thyristor trigger signals directly to the thyristor’s gate. The system measures the excitation voltage Uf, for protection purposes, via a Measuring Transducer MTR. The actual excitation current is measured via a shunt and a DC-to-DC converter, or isolation amplifier. Both voltage and current feedback signals are wired to a Measuring Unit Interface board MUI. The line voltages are measured also by MUI, via a synchronization transformer. MUI sends farther the measured signals to a Measuring Unit Board, MUB, which is an analog to digital converter. MUB is connected with a 96 pins piggyback connector to CCB.

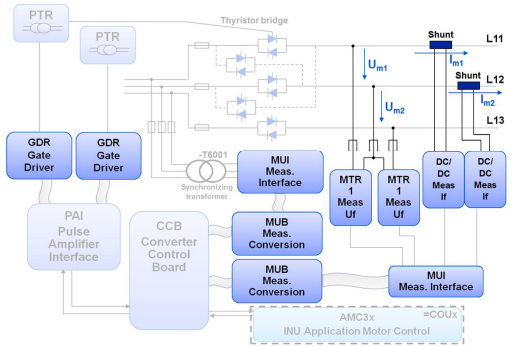

Control Hardware in Brushless Excitation:

The same control boards, except Thyristor Status Board STA, are used in the brushless excitation system. But, in the brushless system, there is no electrical contact between the rotor and the fixed part of the motor. Therefore, the actual excitation current cannot be measured. It is calculated by CCB, based on the mathematical model of the exciter machine and the measurements of the stator values for voltage and current. Two lines to line output voltages, L11 to L12 and L12 to L13, and two currents, Im1 and Im2 are measured. Consequently, the brushless excitation needs two MTR boards, two shunts and two DC to DC converters. Two MUI boards are used also: one for the line voltages via the synchronizing transformer and the second for the exciter currents and voltages. There are also two MUBs, each MUI board being connected to a separate MUB. The second MUB is installed in the top of the first one. The brushless Excitation Unit is equipped with ten thyristors. Since the Gate Driver GDR can control only six thyristors, a second GDR board is needed here. The same PAI board will control both GDR boards.

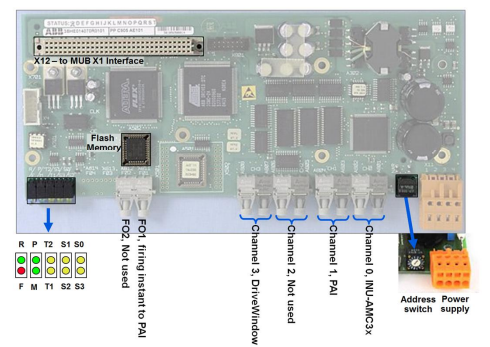

CCB- Converter Control Board:

CCB, Converter Control Board, is the main control board of the Excitation Unit. It takes care of excitation current control, synchronization and firing angle calculations. CCB receives the feedback of the excitation electrical values, voltage and current, and synchronization voltages, from MUB, connected at X12. Except X12, the other communication channels of CCB are four fiber optic DDCS channels, channel 0 to channel 3. CCB communicates with the control board AMC located in the Control Unit of the inverter, via fiber optic channel 0. It receives from AMC the excitation current set point and sends to AMC the actual values and the Excitation Unit status. Channel 1 communicates with the Pulse Amplifier PAI, and channel 3 with

the PC tool, DriveWindow, for programming and troubleshooting. Channel 2 is not used with ACS 5000 Excitation Unit. There is also a fiber optic transmitter FO1, “Firing instant”, connected to PAI. Fiber optic transmitter FO2 is not used with ACS 5000. The rotary address switch S701, close to the 24 VDC power supply connector; has always the address “1”. Ten LED’s indicate the status of CCB. The meaning of the LED’s is: F, Red: Fault; R, Green: not used; M. Green: ON during the booting sequence; P, Green: Power OK ; T1 and T2, Yellow, Traffic, blinking whenever the board communicates either with AMC or with DriveWindow. The flash memory can be programmed using the same hardware and software tools as AMC board.

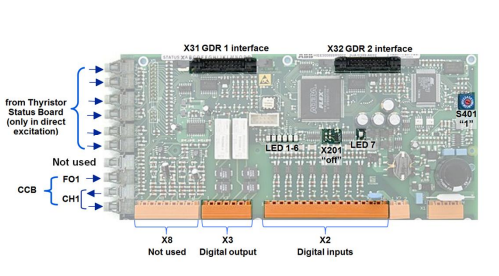

PAI Board or Pulse Amplifier Interface Board:

The Pulse Amplifier Interface, PAI, is a logical “amplifier”. It converts the firing pulses coming from CCB channel 1 in a serial form via a DDCS link, into separate parallel pulses with correct timings. On the other hand, the PAI collects different status information and prepares them to be transferred to CCB via the DDCS link. PAI receives also from CCB the firing instant, via the fiber optic receiver FO1. Six fiber optic receivers are used only in direct excitation, to receive the status of each thyristor. The board has a rotary address switch S401, always “1”, and a jumper X201, always “OFF” in ACS 5000 applications. There are seven LED’s on the board: a separate one, LED7, Auxiliary Power OK, and 6 grouped LED’s, LED1 to LED6. LED1 to LED3 are red, fault LED’s; LED5 and LED6 are status LED’s, green. LED4 is not used. PAI board can control one or two 6-pulse Gate Drivers, via GDR 1 and GDR 2 interfaces. In a direct excitation we need only one GDR board; X31 GDR 1 interface is used. For the brushless excitation, both X31 and X32 are used, to control two GDR boards. PAI has several I/O connectors; the Digital inputs used with ACS 5000 are: DI2 – thyristor fuse status, DI4 – overvoltage from OVP board, only in direct excitation, DI6 – earth fault from the earth fault relay, and DI8 – temperature supervision from a thermostat installed in the cabinet. The used Digital Outputs are: DO1 – RESET overvoltage protection, and DO2 – FIRING overvoltage protection.

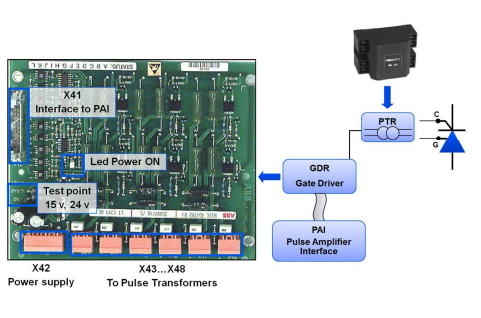

Gate Driver and Pulse Transformer:

The thyristor trigger signals are sent from the PAI board to the GDR board as current signals through a galvanic connection. The trigger signals control the optocouplers with a 5 VDC supply from the PAI board and a 24 VDC supply from the GDR board. They are galvanically isolated from each other. Pulse power for the gate current is taken from an external power supply.

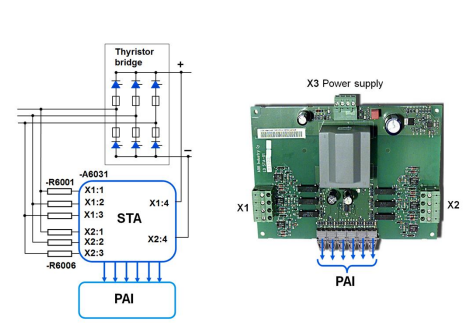

Thyristor Status Board (STA):

Thyristor Status Board STA exists only in direct excitation. It is used for delivering the actual status of the thyristors, conducting or not conducting, to the upper control PAI board and further to CCB board. The indication is based on the voltage measurement over the thyristors. External resistors R6001 to R6006 are used for the high ohmic connection of the input line potentials, but the outputs of the bridge, the plus and minus potentials, are wired directly to the board. The status information is sent to the PAI board with fiber optic cables in order to achieve galvanic isolation between the power stage and the control electronics. STA has six fiber optic transmitters; thus one board is used for the entire six thyristors bridge.

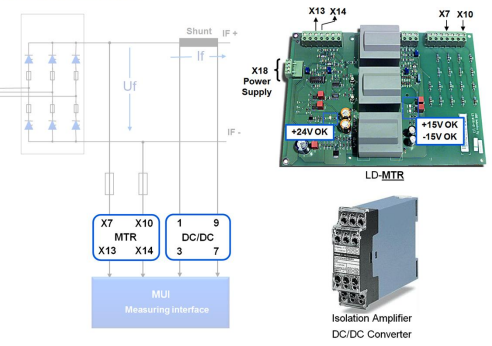

Measurements- Isolation Amplifier:

For the control and protection of the Excitation Unit, we need to measure the output values of Excitation Unit, voltages and currents. The voltage measurement is achieved by the Measuring Transducer: MTR board. Basically, the MTR board is an isolated transducer board which transforms and makes proportional output voltage to input voltage. If the auxiliary power supply for the Excitation Unit is 380 to 400 VAC, the excitation voltage is connected between X7 and X10. If the supply voltage is between 410 and 690 VAC, the exciter output is connected between X5 and X10. The output of MTR board, the voltage proportional with the excitation voltage, is wired to MUI board. The excitation current is measured via the shunt and the DC-to-DC converter or Isolation Amplifier. The output of the DC-to-DC converter is wired also to MUI board. The shunt will convert the excitation current in a small voltage; this small voltage is amplified by the Isolation Amplifier.

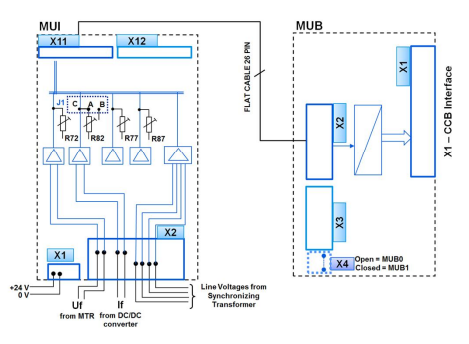

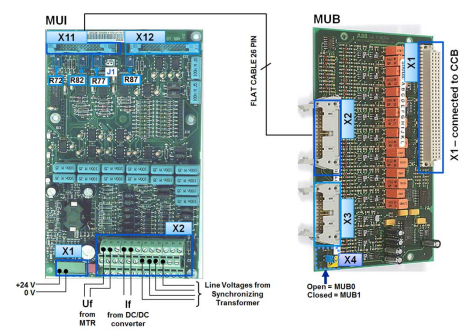

MUI- Measurement Unit Interface and MUB-Measurement Unit Board:

Measurement Unit Interface board, MUI, is a signal conditioner located between the measurement transducers and the analog to digital converter, MUB. The direct excitation has one MUI measuring all the signals, including the synchronizing transformer signals. The brushless excitation has two MUI boards, one for exciter voltages and currents, and a separate one for the synchronizing voltages. The outputs of MTR, DC to DC converter, synchronizing transformer are wired to connector X2 of MUI. A 26-pin ribbon cable port X11 connects MUI to MUB. The MUI board has also outputs for voltage and current meters, not used with ACS 5000. The Measurement Unit Board MUB is an analog to digital interface between MUI board and Converter Control Board, CCB. Again, the direct excitation has one MUB, while the brushless excitation needs two of them, MUB0 and MUB1.

MUI board has only one to one connection, consequently no address jumpers or switches are necessary. However, the board has four trimmers, R72, R77, R82 and R87, not used in applications with ACS 5000. Same thing about jumper J1, it is not used with ACS 5000 and should be left in position A-C. The MUB is connected over CCB via a 96-pin port X1; the second MUB in the brushless excitation unit is connected in top of the first one. MUB has an address jumper, X4, not installed or open for the direct excitation. In a brushless excitation, X4 is open for MUB0 and closed for MUB1.

Earth Fault Detection

An insulation resistance monitoring device is used in the direct excitation converter to detect earth faults in the excitation circuit including transformer secondary side and motor. Device is available as option for the brushless excitation.